Performance characteristics

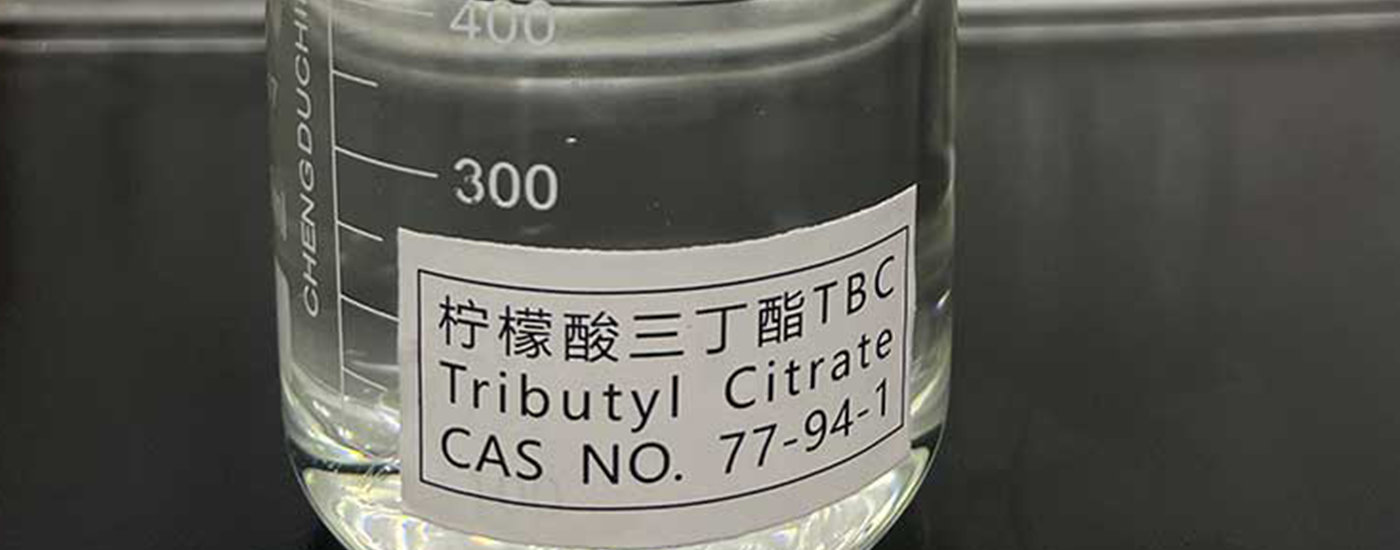

Good plasticizing performance: TBC (tributyl citrate) is a non-toxic plasticizer. It has a good plasticizing effect on a variety of plastics such as polyvinyl chloride (PVC), and can be inserted between polymer molecular chains to increase the spacing between molecular chains, making the plastic soft and elastic. Compared with traditional phthalate plasticizers, TBC does not produce the health risks that phthalate plasticizers may bring.

High stability: TBC has excellent thermal stability and light stability. In high temperature environments, plastic products plasticized with TBC are not prone to decomposition, discoloration, etc. Under long-term lighting conditions, the performance and appearance of plastic products can also be maintained, effectively extending the service life of plastic products.

Low volatility: Its volatility is low, which makes it difficult for TBC to evaporate from the inside of the plastic during the use of plastic products, thereby ensuring the long-term stability of the physical and chemical properties of the plastic. For example, in plastic products such as automotive interior parts, low volatility can reduce the generation of odor in the car.

Good water resistance: TBC has good water resistance. When plastic products containing TBC are exposed to water or in a humid environment, it will not be easily extracted by water, which will not cause the plastic products to become hard, brittle, and other performance degradation.

Good compatibility: It has good compatibility with many polymer materials such as PVC and cellulose plastics, and can be evenly dispersed in these materials without phase separation, ensuring the quality and performance uniformity of plastic products.

Application areas

Plastic products industry: It is widely used in soft PVC films and sheets such as food packaging and pharmaceutical packaging. Due to its non-toxic properties, it meets the safety requirements of food and pharmaceutical packaging, can provide good flexibility and transparency, and makes packaging materials easy to process and use.

Daily necessities: It is used to manufacture various PVC daily necessities, such as toys, stationery, soles, etc. It can make these products have appropriate softness and elasticity while ensuring the safety of the products. Especially in the manufacture of children’s toys, the non-toxic nature of TBC is crucial.

Coatings: It is added to certain coating formulas as a plasticizer to improve the flexibility and adhesion of the coating. For example, in some water-based coatings, TBC can help the coating adhere better to the surface of the coated object, and after drying, the coating has a certain elasticity and is not easy to crack.

Ink: Using TBC in ink can adjust the viscosity and drying speed of the ink, while improving the adhesion and flexibility of the ink on the printed material. It is suitable for printing inks on different materials, such as paper, plastic film, etc.

Medical industry: Due to its non-toxic and good biocompatibility, it is also used in some medical plastic products, such as medical catheters, infusion bags, etc. It can ensure the safety of these medical devices while ensuring their softness and elasticity, and reduce potential harm to the human body.

Application method

Direct addition method: During the plastic processing process, TBC is directly added to the plastic raw material in a certain proportion. For example, in PVC processing, TBC is usually added to a high-speed mixer together with other additives such as PVC resin, stabilizer, lubricant, etc., and mixed at a certain temperature (such as 80-100℃) and speed for a period of time (such as 10-20 minutes) to make TBC evenly dispersed in the PVC resin, and then extrusion, injection molding and other molding processes are carried out.

Solution addition method: In the coating and ink industry, TBC is sometimes dissolved in a suitable solvent to form a uniform solution, and then the solution is added to the coating or ink formula. For example, in water-based coatings, TBC can be dissolved in a small amount of organic solvent or aqueous solvent (such as ethanol, ethylene glycol, etc.), and then mixed with other components of the coating (such as water, emulsion, pigment, etc.), and stirred to ensure that TBC is evenly distributed in the coating.