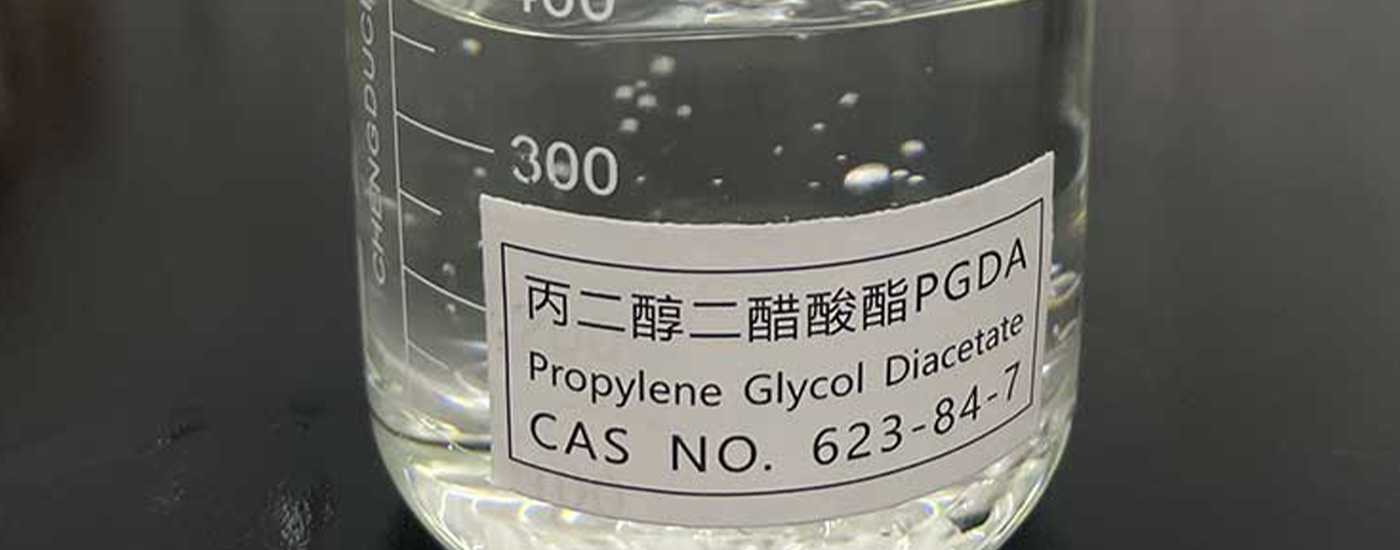

Performance characteristics

Good solubility: PGDA (propylene glycol diacetate) is an environmentally friendly solvent with a high boiling point. It has good solubility for many organic substances and can dissolve a variety of resins, paints, coatings, etc. For example, it can dissolve acrylic resins, polyester resins, etc., which makes it play an important role in the coating and ink industry.

Low toxicity: Compared with some traditional organic solvents, PGDA has lower toxicity. This makes it more advantageous in application scenarios with high requirements for the environment and human health, reducing the harm to the health of operators and pollution to the environment during use.

Moderate volatility: Its volatility is moderate, neither too fast to cause problems such as poor leveling of the coating during the drying process, nor too slow to affect work efficiency. During the drying process of the coating, it can evaporate in an orderly manner, which helps to form a uniform and smooth coating surface.

Chemical stability: PGDA has good chemical stability and is not prone to chemical reactions such as decomposition and oxidation under general chemical environments. This allows it to exist stably in different chemical formulas and maintain good performance when mixed with other chemicals.

Application areas

Coatings and paints: In wood paints, PGDA can be used as a solvent to dissolve resin components, help paints adhere better to the wood surface, and form a smooth and hard protective film after drying, improving the wear resistance and aesthetics of wood.

In automotive paints, it helps to improve the fluidity and leveling of paints, making the coating on the surface of the car smoother and brighter, and also enhances the weather resistance and corrosion resistance of the coating.

Ink: In printing inks, PGDA can be used as a solvent to adjust the viscosity and drying speed of inks. For example, in plastic film printing, it can make the ink better adapt to the plastic surface, improve the printing quality, and ensure the clarity of the pattern and the vividness of the color.

Industrial cleaning: Used to clean oil and dirt on metal surfaces. Due to its good solubility, it can effectively remove impurities such as oil and grease left in the metal processing process, and there is less residue after cleaning, which will not cause corrosion to the metal surface.

Application method

Direct use as a solvent: In the formulation of coatings, inks, etc., PGDA can be directly added as a solvent component. According to the specific product requirements and formula, it is mixed with other ingredients such as resins and pigments in a certain proportion, usually under appropriate stirring conditions to ensure uniform mixing. For example, when formulating a wood paint, PGDA can be stirred and mixed with acrylic resins, pigments and additives at room temperature to make a uniform paint.

Used for dilution: When the viscosity of the paint or ink is too high, PGDA can be used as a diluent to adjust the viscosity. In this case, just add an appropriate amount of PGDA slowly to the product to be diluted and stir continuously until the desired viscosity is reached. For example, for some high-viscosity printing inks, a small amount of PGDA can be added to reduce the viscosity and improve the printing suitability of the ink.