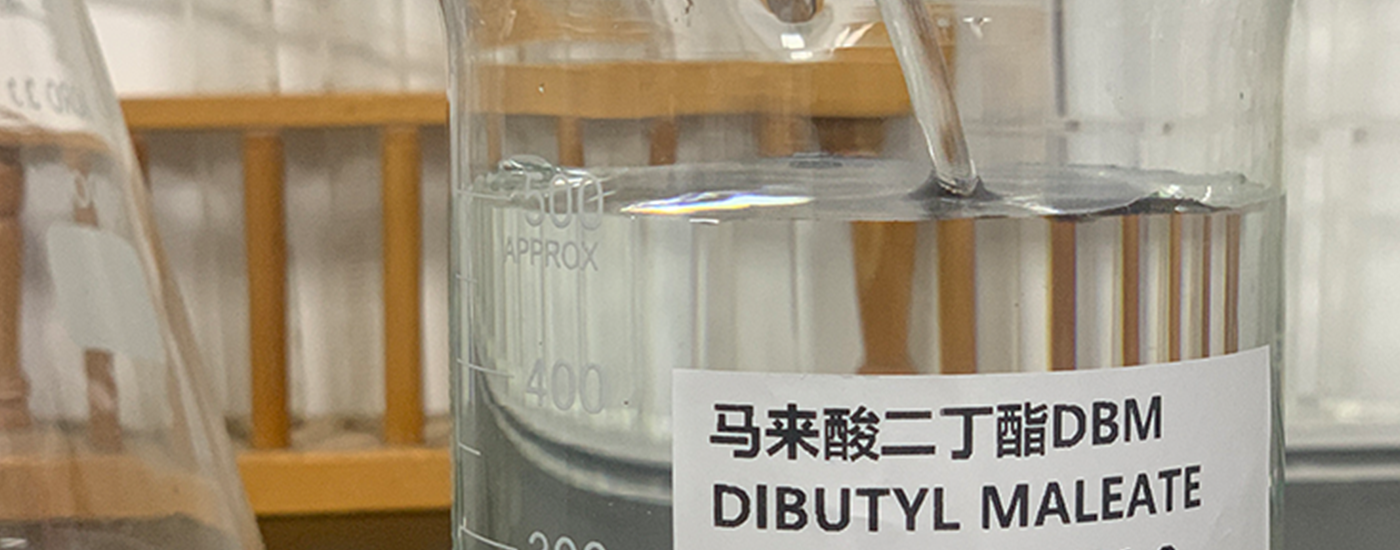

Performance characteristics

Good compatibility: DBM has good compatibility with a variety of polymers and can be evenly mixed with high molecular materials such as polyvinyl chloride, vinyl chloride-vinyl acetate copolymer, polystyrene, polymethyl methacrylate, etc., thereby improving the performance of these polymers.

High plasticizing efficiency: When used as a plasticizer, DBM can effectively reduce the glass transition temperature of the polymer, increase the flexibility and mobility of the polymer molecular chain, and make the product have better softness, elasticity and cold resistance, and still maintain good physical properties at lower temperatures.

Low volatility: The molecular structure of DBM is relatively stable and has low volatility at room temperature, which makes it more durable in the polymer, can maintain the plasticizing effect for a long time, and reduce the performance degradation and environmental pollution caused by volatilization.

Strong stability: It has good light stability and thermal stability. During processing and use, it can resist the influence of factors such as light and heat, and is not easy to decompose and deteriorate, thereby extending the service life of the product.

Low toxicity: Compared with some traditional plasticizers, DBM has low toxicity and relatively less harm to the human body and the environment, which meets environmental protection and safety requirements.

Application fields

Adhesives: DBM can be used as an additive for plasticizers and solvent-based adhesives, which can improve the viscosity, flexibility and water resistance of adhesives, enhance the adhesion to different materials, and is widely used in the bonding of wood, paper, leather, plastics and other materials.

Inks and coatings: Adding DBM to inks and coatings can improve their fluidity, flexibility and glossiness, improve the adhesion and durability of the coating, and reduce the viscosity of inks and coatings, making them easier to apply and dry, and suitable for various printing and coating processes.

Chemical intermediates: DBM is an important chemical intermediate that can be used to synthesize other organic compounds. For example, by reacting with alcohols, amines, etc., it can prepare compounds such as esters and amides with different properties, further expanding its application range in the chemical industry.

Plasticizer: DBM is an excellent plasticizer for plastics such as polyvinyl chloride. It can significantly improve the softness, tensile strength and elongation at break of plastics, making it more suitable for the manufacture of various plastic products, such as films, pipes, wires and cables, soles, etc.

Application

Direct addition: In the production process of adhesives, inks, coatings and plastics, DBM can be directly added to the raw material system, fully mixed with other ingredients, and then subjected to corresponding processing techniques, such as stirring, grinding, extrusion, injection molding, etc., to play the role of plasticization and performance improvement.

Copolymerization: DBM can participate in copolymerization and polymerize with other monomers to form polymers with specific properties. For example, when synthesizing vinyl chloride-vinyl acetate copolymers, adding DBM as a comonomer can adjust the molecular structure and properties of the copolymer to obtain the desired flexibility, viscosity and other properties.

As an additive: In addition to being the main plasticizer or comonomer, DBM can also be used as an auxiliary additive. For example, in some coatings, adding a small amount of DBM can improve the leveling and gloss of the coating; in adhesives, adding DBM can adjust the properties of the adhesive such as the open time and curing speed.